PORTABLE WELDING MANIPULATORS

POWERED SUBARC WELDING MANIPULATOR

POWERED SUBARC DEMO

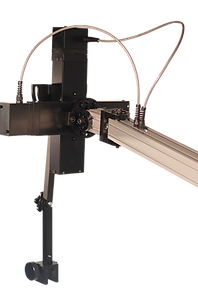

The Powered SUBARC unit is a portable welding manipulator designed for non-oscillated welding applications, equipped with motorized X and Z axes for enhanced control and ease of use. It is ideal for submerged arc welding (SUBARC) with pressurized or gravity feed flux systems, and also supports cold feed TIG, MIG, solid core, and flux core applications. This unit builds on the adjustability of the manual version with powered slides and single-hand D-pad control, enabling greater precision and operator efficiency. It performs best on horizontal workpieces up to six feet in diameter, while vertical applications have no diameter restriction. It is also highly effective for cladding applications in repair jobs.

Description:

-

Portability & Mobility: Mounted on a base with four swivel casters (two locking), allowing easy repositioning in the shop or field.

-

Adjustability: Offers nine different axes of adjustability for precise torch positioning.

-

Powered Motion Axes:

-

Replaces manual slides with motorized X and Z axes.

-

Controlled by a single-hand D-pad controller with directional inputs (up, down, left, right).

-

Features a central “rapid” button that provides two-stage speed control—fast for positioning, slow for welding.

-

-

Integrated Wire Feed Control: Allows the operator to start and stop the weld arc directly from the hand controller for seamless arc control during welding.

-

Compatible Welding Applications:

-

SUBARC (submerged arc welding) with gravity feed or pressurized flux systems.

-

Cold feed TIG, best suited for workpieces six feet in diameter or less.

-

MIG welding applications.

-

Solid core and flux core wire applications (ideal for horizontal welding on workpieces six feet in diameter or less).

-

Cladding applications for repair jobs.

-

Best Use Cases:

-

Horizontal SUBARC welding with gravity feed or pressurized flux systems.

-

Rotational welding on positioners or pipe rolls, for workpieces up to 6 feet in diameter.

-

Cold feed TIG applications, in horizontal orientations up to 6 feet in diameter.

-

Dragging MIG, solid core, or flux core wire in horizontal setups.

-

Cladding for repair jobs, where precise control and ease of operation are essential.

-

Vertical applications are not limited by diameter.

The Powered SUBARC unit combines the flexibility of the manual version with powered control, two-speed operation, and integrated weld start/stop, making it an ideal solution for improving welding consistency and operator comfort across a variety of welding processes.